A clean whiteboard is a joy to use. One featuring long-lived stains from past use, is not. This article provides you with the understanding needed to ensure you – and your whiteboard – stay in the first category!

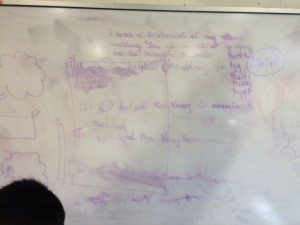

This problem has been around for as long as whiteboards have been, so the image at right will look familiar to many readers. Every few months a customer asks me for advice on how to clean a particularly reluctant surface. In this recent (and typical) example the problem was evident on several whiteboards in use. The question was raised: is our whiteboard surface material up to the required standard for use with dry-erase marker pens?

In a nutshell, my answer was: Yes, it is. Enamel steel is by far the highest performing surface for dry-erase capability. In this case, the visual evidence points to familiar culprits: ink that in my opinion should not be described either as “dry” or “eraseable”, and usage patterns which need improvement.

Stepping through the key issues:

- Use good markers: Smearing of ink when wiping off is a strong clue that what is being cleaned contains oils or greases, not just dry ink pigment.

- Clean early to avoid staining: It’s evident from description and from the images that the staining has been there for a very long time.

- Regularly restore to an as-new surface: Whiteboard surfaces must be glossy and perfectly clean if they are to dry-erase correctly. Stained, cloudy or smudged surfaces indicate residual contaminants on the surface. Any porosity or surface contaminants provide an “anchor” for new ink residues, making these impossible to remove and aggravating the problem. Remember to regularly put in the effort to “restore” your surface to as-new condition, in order to ensure its continuing high performance.

- NEVER scour your board with any abrasive cleaner or object. Doing so will gouge minute scratches into the surface, and these scratches serve to hold contaminants in, making them harder to erase and clean.

To remedy a board which has reached the condition shown will take a good deal of effort and some powerful (safe) cleaners. But since you’re using an excellent enamel-steel surface, your effort will be rewarded: the surface will restore to as-new condition provided that it has not been scoured in some way.

Clean the board with an appropriate cleaner: isopropyl alcohol based, or failing that, methylated spirits. You’ll find that household glass cleaners such as Windex work well; these will generally be ammonia or alcohol based (or both). Most commercial whiteboard cleaners are alcohol based, but may be a little weak for the hard work. The higher the concentration of isopropyl alcohol the better (but wear gloves, and of course avoid smelling or drinking the stuff!) These solvents will not damage the surface, nor will they affect the plastic perimeters associated with the optics.

I find that a paper towel works best to wipe on and wipe off the cleaner, repeatedly rubbing the ink stains hard to dissolve them and clean them off perfectly. Keep going until EVERY LAST STAIN IS GONE. If any is left, the cycle will start again immediately. Needless to say, the older the stain the longer this takes and the more effort is involved.

After much effort, the surface will come up to the original surface sheen. If it does not, the cleaning is not good enough; just keep at it until it is as good as new.

(The only exception to this is if some abrasive cleaner has been used on the surface at some time in the past; this is not possible to remedy and it will certainly greatly deteriorate the dry erase performance of the surface).

The important point is – unless it is absolutely clean, NO WHITEBOARD will work as intended. You have to do whatever it takes to get to that point.

On-going use of your whiteboard

Use only markers which exhibit excellent dry-erase performance. Try markers out by applying ink to the surface, waiting just a few seconds, then wiping it off with a dry, clean rag (or eraser). There should be no smearing whatsoever, and no residue or even “shadow” left behind. If you have to wait for more than a few seconds before the ink dries, or if it smears at all when erasing it, or if it leaves a film of any sort after erasure– then you should be looking for another brand of marker.

What’s happening? “Good” whiteboard markers ideally utilise volatile solvents to carry the ink pigments. These solvents boil off quickly aftr application to the surface, leaving a very dry “ink” powder residue which then wipes off easily. In warm climates particularly, such markers don’t last long since all the solvent evaporates quickly leaving the marker useless. Administrators are understandably receptive to suppliers promoting markers which last longer, don’t smell etc. To achieve these claims, suppliers are changing the carrier fluid in the ink. Unfortunately, less volatile carriers simply don’t perform as well in terms of dry erasing.

Always erase whiteboards immediately after use. Try not to leave the ink on the board as it will be far harder to clean in a day or two, and much worse again in a few weeks. (Of course we all leave some ink on the boards for a while – just be aware of the impact this has and the fact it will be harder to remove).

Remember to frequently restore (ie clean) the surface back to a perfectly clean standard. Every little impurity on the surface contributes to an escalation of the problem.

A properly cleaned board is very easy to wipe clean immediately after use. A slightly dirty board is far harder to clean, as the new ink attaches to the old ink residues.

Dirty boards become impossible to use very quickly.

Other useful resources: